From protecting homes from drywood termites to eliminating pests in shipments of food and agriculture products arriving at ports on both coasts, fumigation has proven its value again and again.

What is in doubt is the products the pest management industry has used to deliver fumigations. The shrinkage of the fumigators’ toolbox has been well-documented over the last decade.

Despite the loss of products and ever-tightening regulations, pest management professionals and a new generation of food industry and agriculture professionals have learned to adapt and earn an appreciation for what fumigation brings to the table.

The millions of bags of cocoa beans that are imported annually into the United States arrive on docks in Philadelphia and are fumigated before being taken to warehouses — where they can be stored for up to a year.

This represents a new way of thinking that is a direct result of the push for more comprehensive food safety regulations and consumer demands that the products they buy be free of any threats.

In the past many didn’t consider food shipments as a “real” commodity until they arrived at the processing plant. The Food Safety Modernization Act (FSMA) has made it clear that food warehouses and distribution centers are part of the process and they are increasingly under the microscope when it comes to inspections to prevent cross-contamination of products.

Fumigations also protect homes, apartment buildings and historical structures – like the 80-foot mast of a historical ship in South Carolina that was infested by both drywood and Formosan termites.

PCT magazine spoke with several pest management professionals who are actively engaged in fumigation work to get a pulse on this important market segment.

Q. Are you seeing an increase in the demand for fumigation work in your market area?

Jeff Waggoner, A.C.E., Vice President/General Manager, Fumigation Service & Supply: Fumigation of export products is rising as is the food distribution segment. Agriculture markets, especially seeds, flour and milling operations are strong but commodity fumigations of grain ebb and flow with the market. If facilities are storing grain and other products long-term we see greater demand. The food-processing sector has leveled off because of philosophical changes on the client’s end and cost considerations.

Clients are using fumigation more creatively than in the past. Newer distribution and processing facilities are constructed better and are more efficient at keeping pests out. We are seeing demand for more specialized, targeted applications.

Derek Johnson A.C.E., District Manager, Gregory Pest Solutions: In residential markets when you see an uptick in bed bug or drywood termite pressure there will be higher demand for fumigations. I see more pest management companies looking at fumigation services but the expenses involved in starting up a fumigation division — equipment and training — can be a deterrent.

On the commercial side, fumigation will always be part of commodity business from rail cars to shipping containers. In our region the fumigation of pine logs being exported to China and India is mandated by the U.S. Department of Agriculture.

Kurt Reichert, Fumigation Director, Western Fumigation: Fumigation services have enjoyed a strong market over the last several years. This has been driven by a number of factors. The relevance of certain pests such as bed bugs and the brown marmorated stink bug has pushed the need for fumigation services.

Changes in the phytosanitary program in China have led to a resurgence in the need for log fumigation. Many of the logs harvested for export are grown in the eastern half of the U.S., and ports on the East Coast are searching for fumigation sites that can handle volumes not seen in recent years. More phytosanitary inspections by agricultural officials in the U.S. and abroad have also led to increased pest interceptions which may require fumigation services to control.

For example, Australia and New Zealand have started to see the brown marmorated stink bug arriving on certain imported goods. It is a serious agricultural pest in addition to being an annoyance, but it is not yet established in Australia or New Zealand.

To avoid the pest becoming established there, for shipments arriving between September and April, both countries are requiring imported loads of certain “at risk” goods be treated, and fumigation is one of the most frequently deployed options.

Lance Gray, Regional Manager, Sprague Pest Solutions: Many of our clients have high value commodities that need to be protected. In Oregon, fumigation of grass seed, flour and other grain storage and processing facilities has been very consistent.

Fumigations can be a preventive or reactive approach to solving a pest issue depending on the client’s situation. We always look at the pest trend data in the facility and tailor the approach to suit the facility — it is never a cookie-cutter process.

Certain food manufacturing processes and products attract higher levels of pest activity. The seed warehouses I mentioned can have product stacked on pallets up to the ceiling and the mice do not have to leave the pallet for food. In this case fumigation is an effective solution to manage the threat.

Q. How have food safety mandates changed the demand or need for fumigation?

Waggoner: FSMA was a good thing for the industry since it affords us the chance to really get to the heart of pest issues, emphasize prevention and stress integrated pest management (IPM) practices.It has been a selling point for fumigation services, which we view as a preventive step. QA managers and sanitarians can break insect life cycles with routine fumigations and protect their products and brand in the process. It is not just blindly fumigating a structure but doing a targeted, data driven service that will leave no surprises for the client. It can be an effective part of an overall IPM program.

The increase in U.S. FDA-driven product recalls has caused companies to invest more in food safety and pest management practices. It used to be that managers felt they failed if they had to fumigate, but the new generation understands that fumigation is still a reliable tool that can keep them out of bad pest situations.

Johnson: We have always stressed an IPM approach and worked with clients to achieve pest management goals through sanitation, GMPs and maintenance. We don’t view fumigation as a preventive measure unless we are doing commodity fumigation. Product loss due to pest-related issues can have a big bottom line impact on clients and commodity fumigations can help keep that in check.

Reichert: Since it was signed into law in 2011, FSMA has been a buzzword in the affected industries, many of which fumigators have been historically involved with. Although fumigation is not necessarily the choice when it comes to control of biological agents, it remains the easiest, quickest and most cost-effective way to deal with pest adulteration of food items, the trucks and trains which transport them, as well as the warehouses where they are stored.

The increased scrutiny on how FSMA-covered items are produced, transported and stored has led to fumigation becoming an important tool in the FSMA compliance toolbox, which has certainly led to increased business for fumigation companies.

Q. What don’t clients understand about the value of fumigation services?

Waggoner: Clients don’t always appreciate the resilience of pests to circumvent even the best pest management programs. Pests will always try and access a facility or product, and can become a deep rooted problem in the distribution and retail channels if they aren’t eliminated. We have to make sure our clients are accepting and sending unadulterated product. Our job is to make sure all the options — including fumigation — are considered. Each facility has unique needs and we need to identify — based on trend data and results — what works for them.

Johnson: Newer QA and facility managers may not be as familiar with fumigation as their predecessors. They want to know more and want less of an impact. We tell them they can invest in traditional pest management practices, including fumigation, or work to correct sanitation and cultural issues and make repairs to the structure that will lower the pest threat. They often opt to fix the internal issues first and that is a good thing. My job, at the end of day, is to protect clients’ brand and my brand, and if I coach them through and give them answers that work, we both win.

Gray: There are two schools of thought when it comes to fumigation as a pest management tool. The old school approach is we’ve always done our pest management this way — with or without fumigation — so why change. The next generation of QA and facility managers wants to understand the science behind fumigation, where it fits into their pest program and the cost benefit. They are looking for value and effectiveness, which we will help them find.

Q. What does the future of fumigation look like?

Waggoner: I see a future where the safe and effective use of fumigations will continue to benefit people, products and environment. There is a limited toolbox and we have to be good stewards of that and focus on education and training. Without fumigation the costs for food production will increase because of spoilage due to insects and rodents. We as an industry must be ready to smartly apply the tools we have and help reduce the risk to consumers. The future need is there and there is a lot of potential for those willing to do it right.

Johnson: Fumigation will always have its place in the pest management industry but regulations, safety mandates and upfront investment will make it harder for smaller startups.

The growth of the market will also be impacted by the buying decisions of a new generation of clients. They will do their due diligence to make sure we are doing it right and fumigation may not always be the first option. More emphasis will be placed on preventive methods to reduce pest [pressure] and fumigation may not look the same as it does today but it will still be there. If pest management professionals emphasize safety and education and invest in quality staffing, fumigation can be a successful part of their business.

Gray: There will always be a need for fumigation services, especially as the food processing and distribution market grows and adds more capacity. An investment in fumigation can be small compared to the potential risk contaminated food products present to consumers and food processors. With product recalls on the rise, food processors want to protect their brand and customers, and fumigation can be a cost-effective option.

The author is partner in B Communications.

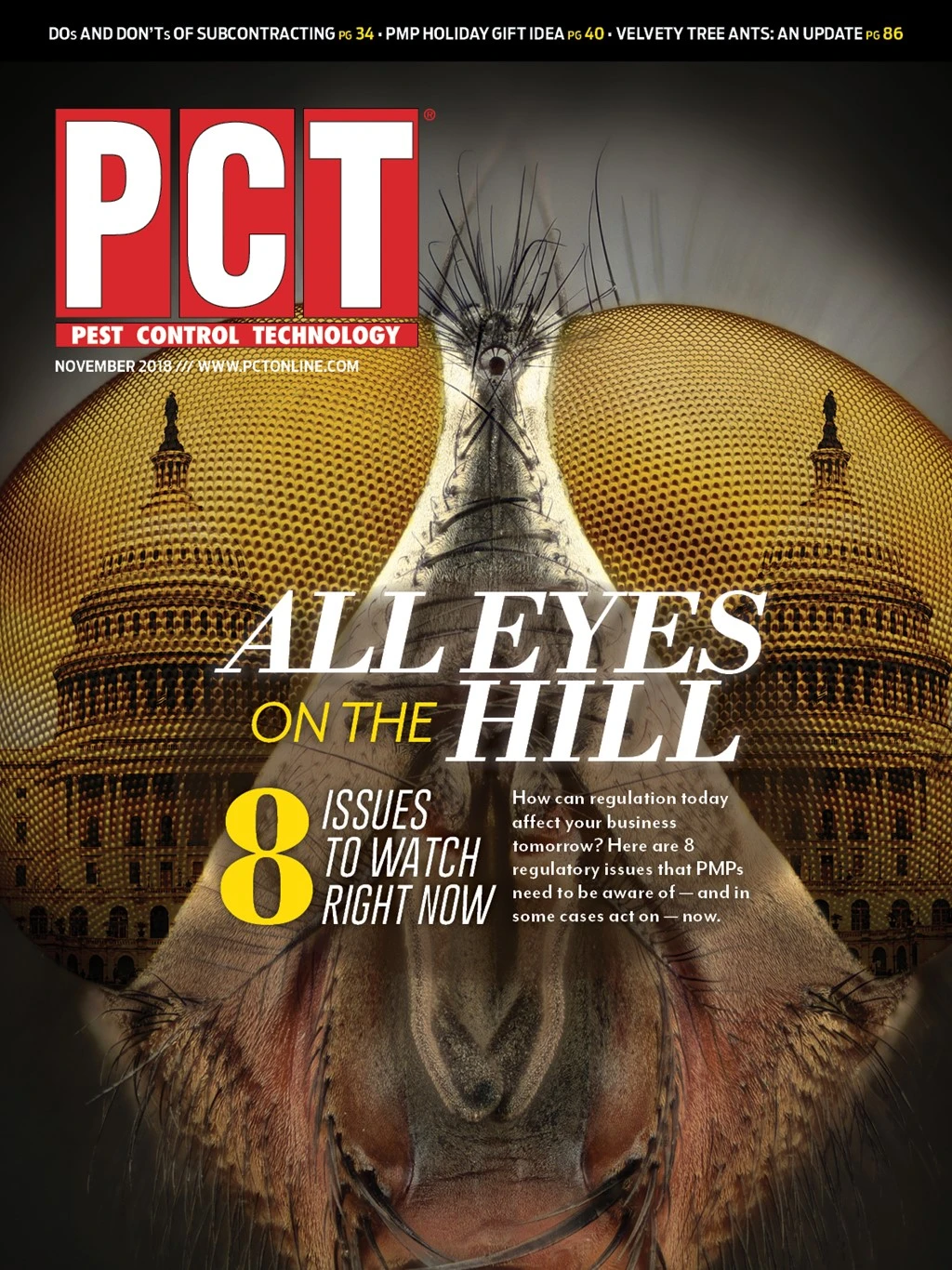

Explore the November 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Pest Control Technology

- Rentokil Terminix Expanded in Key Markets with 2024 Acquisitions

- In Memoriam: Joe Cavender

- Certus Acquires Green Wave Pest Solutions

- Liphatech Adds Alex Blahnik to Technical Team

- Do the Right Sting: Stinging Insect Identification, Management, and Safety

- VAGA's 8th Annual Veterans Thanksgiving Appreciation Dinner

- Clark's Blair Smith on the Response to Increased Dengue Fever Cases in Southern California

- WSDA, USDA Announce Eradication of Northern Giant Hornet from U.S.